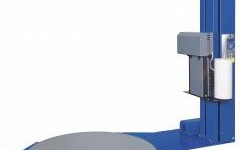

Key Points When Purchasing A Power Pre-Stretch Pallet Wrapping Machine

-

There are some key points of interest when purchasing a quality power pre-stretch pallet wrapping machine.

These points relate to Health & Safety regulations that should be considered during the purchasing process.1. The product should sit within the confines of the turntable

2. A power pre-stretch machine must have a broken film detector to automatically stop the turntable and the power pre-stretch

unit in the event of film breakage.

This prevents the film from wrapping around the power pre-stretch rollers cause a film jam and potentially a trip hazard

3. Do not use sharp implements on the embossed rubber rollers, any tear in the ruber will automatically tear the film when

stretched, thus resulting in a trip hazard

4. Always keep the area of pallet wrapping clear, a quality machine will pick up on debris under the safety plate and when

the carriage returns to it’s zero position it will detect the debris and shut down the machine operation. Debris would

need to be removed by the operatorFor more help and information on choosing the right pallet wrapping machine for your application please speak to Paul on 0116 2790005 or email at pmccarthypmd@aol.com